Shock Cell

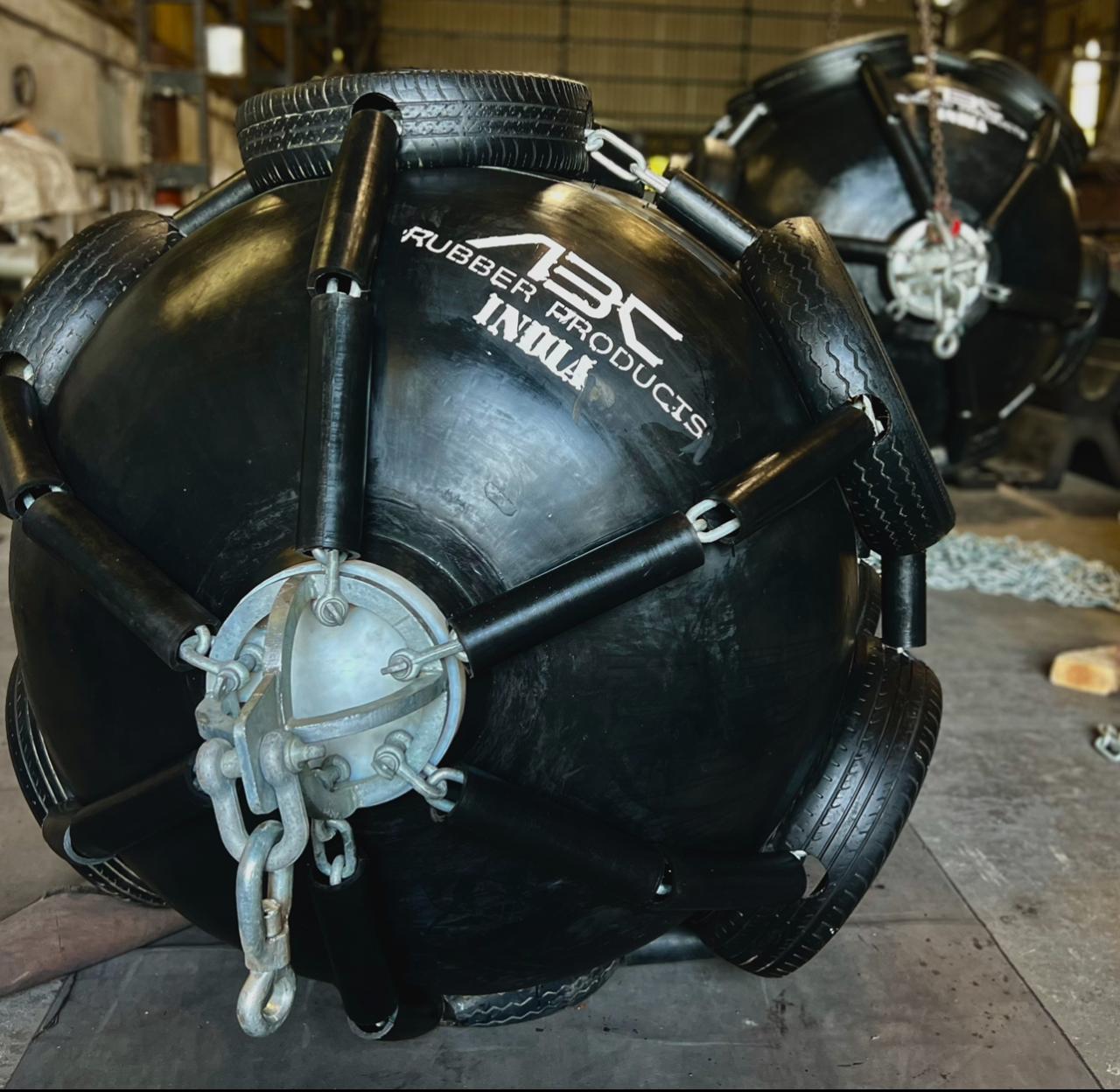

"hippo" Shock Cell offers reliable and efficient protection for offshore platforms. The Shock Cell is based on our expertise in manufacturing specialised rubber products for the marine industry and can operate under even the most extreme offshore weather.

It is simple to install, and maintenance-free. Prior to delivery, every unit is load tested. Shock cells are manufactured in a wide range of sizes depending on the load and diameter of the jacket leg. Additionally, the shock cell can be supplied with an eccentric bumper ring

FEATURES

- Absorbs the energy of a barge or vessel

- Protects the jacket leg during berthing of

- vessels

- Supports the boat landing structure

- Excellent Axial load taking capacity

- Offshore Platform Jacket structure

- Boat landing structure

- Barge bumpers

TYPES OF SHOCK CELLS

SHOCK CELL

"hippo" Shock Cell offers excellent energy absorption even at high angles. Two co-eccentric tubes are bonded with specially designed rubber elements in middle. This arrangement leads to a very strong bond and allows for high deflections and low reaction. Shock Cell can absorb energy both in compression and torsion It is having extremely good resistance to both axial and bending.The high-tensile rubber compound guarantees outstanding resilience and good mechanical strength. They work well in harsh climatic conditions and are appropriate for the marine environment. Excellent resistance to seawater, UV radiation, and ozone aging is provided by a special compound design. Used frequently in conjunction with an eccentric rubber ring and a bumper post it absorbs berthing energy and compensates for tidal variations. It prevents structural damage by absorbing the berthing energy and gives low reaction force to the hull of the vessel.

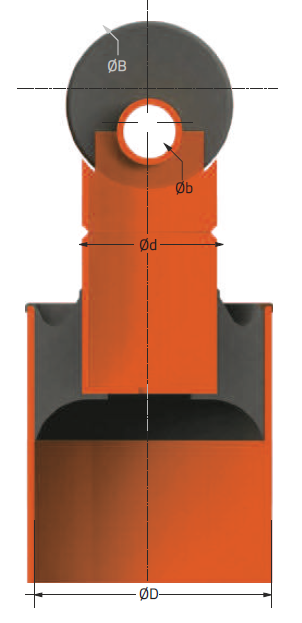

SHOCK CELL WITH EBR

The Boat Landing System consists primarily of the Shock Cells, Eccentric Bumper Rings (EBR) and a steel contact surface. On impact by a berthing vessel, the steel surface transfers the load to the EBRs and the Shock Cells. Kinetic energy is absorbed and dissipated as heat and a smaller reaction force against the vessel by the rubber as it undergoes shear and tension.

The load is therefore reduced, and the vessel can berth without damaging the platform structure. The strong bonding achieved between the rubber and the steel during the manufacturing process ensures that this arrangement will safely dissipate and reduce the external load without damaging the platform.

.jpeg)

_11zon.jpg)